WHY CHOOSING WIT AIRLESS PAINTING MACHINES

The founders of W.I.T. Ltd. have 40 years of experience in the painting industry. They began their venture in the 1970s: a company dedicated to the production of complete automatic painting equipment and painting machines. Over the years they expand their range making it one of the most comprehensive in the industry.

Today W.I.T. Ltd., with a staff of engineers and skilled technicians in step with the latest technology, designs, experiments and builds its own equipment, testing every detail so that it can guarantee the highest quality to its customers.

Over these years, W.I.T. Ltd. has received and repaid the trust of more than 5,000 customers, because what characterizes the people who work there is their passion for their work and the continuous development of their skills. In W.I.T. Ltd. you will find helpfulness, flexibility and the ability to listen to the customer’s needs and, above all, the ability to interpret, understand and implement them.

EFFICIENCY AND QUALITY

In terms of effectiveness, our pumps are designed to reduce waste. Because they do not require compressed air, all the sprayed material is efficiently used to cover the desired surfaces. WIT airless pumps offer a better surface finish because of their ability to spray the material in fine, uniform particles. This results in a smoother and more professional finish than traditional application techniques.

EASY MAINTENANCE

WIT airless pumps are also generally appreciated for their ease of maintenance, especially when properly treated. By following some good maintenance practices and paying attention to the recommendations given, the airless pump will remain efficient and functional for a long time, ensuring high-quality results and minimizing downtime.

ITALIAN INNOVATION

The innovation that WIT engineers have brought to the field of airless pumps has been remarkable. WIT has a long tradition of excellence in manufacturing airless spraying and injection systems, which include: Advanced Atomizing Technology, High Quality Materials, Advanced Control Systems, Integrated and Compact Solutions, and Energy Efficiency.

OUR HISTORY40+ YEARS OF INNOVATIONS

WE PROJECT SOLUTIONS FOR YOUR DAILY WORK

W.I.T. S.r.l. invests significant resources and pays special attention to the research and development of innovative systems and technological solutions to be presented in new products. The design office with some of the most modern and sophisticated tools coordinates the project phases.

New products and accessories are designed and developed with the participation and cooperation of customers.

The most obvious aspect of this commitment is the attention to detail, specially designed with the goal of optimizing efficiency, reliability and use.

Modifications and upgrades of existing products are developed, verified and tested by trained personnel, who confirm the actual benefits.

Product improvements, once approved, are transferred and integrated into series production to ensure continuous and sensitive progress and to meet concrete market needs.

PROFESSIONALS AT WORK

Research & development

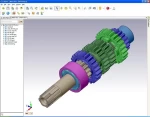

All products are studied, designed and realized in every single detail by WIT specialized staff in order to guarantee the highest quality of the product. Thanks to the use of the highest technologies available our staff can develop the wide ideas to the aim to satisfy the numerous market’s requirements.

Technical & design

Our technical office, using the most advanced informatics’ systems, develops and manages all the technical designs, the explosion drawing, the instruction manual and all the necessary documentation of the products.

Equipment and Accessories Assembling

All the equipments and accessories are assembled by the specialized staff , in production lines, that assure high productivity and operating flexibility.

Equipments and Accessories

Every single product, equipment and all the accessories, are controlled and fully tested on the test-benches by the competent staff before every shipment.

Warehouse

It is divided into two main areas; the first for spare parts and components and the other for finished products, in order to facilitate and speed up all products loading and unloading procedures. Questo per facilitare e accelerare tutte le procedure di carico e scarico dei prodotti.

Technical Maintenance

A part to which we give much importance is without any doubts our technical service department that follows in a rapid and professional way all customers’ needs.

WIT: AIRLESS AND INJECTION MACHINES